Industrial news

Tempered Glass Production Process

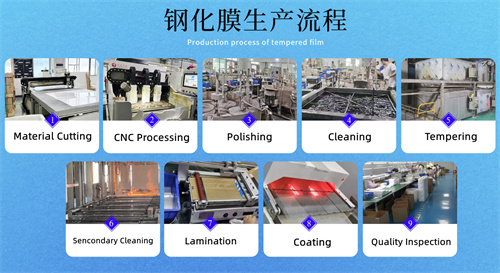

At COSMOND, every tempered glass protector undergoes a meticulous and systematic production process to ensure exceptional quality and durability. Here's a step-by-step overview of our production process:

Material Cutting: High-quality raw glass materials are carefully cut into precise dimensions to fit various screen sizes.

CNC Processing: Advanced CNC machines shape the glass with precision, creating smooth edges and ensuring exact specifications.

Polishing: The glass is polished to remove any imperfections, resulting in a smooth and transparent surface.

Cleaning: The glass undergoes a thorough cleaning process to eliminate dust and debris, preparing it for further processing.

Tempering: The glass is strengthened through a specialized tempering process, significantly enhancing its durability and resistance to impact.

Secondary Cleaning: After tempering, the glass is cleaned again to ensure it is spotless and ready for the next steps.

Lamination: A protective layer is precisely applied to enhance the glass’s functionality, such as anti-glare, anti-blue light, or privacy features.

Coating: Special coatings are added to make the glass smudge-resistant, anti-fingerprint, or anti-reflective, depending on the product specifications.

Quality Inspection: Each piece undergoes rigorous quality control to ensure it meets our strict standards before packaging and shipment.

This detailed process reflects our commitment to producing high-performance tempered glass products that protect and enhance touchscreens for automotive and consumer electronics.

Related News

Categories

Contact us

Dongguan Cosmond Technology Limited

Contact:Judy Guo | Key Account Manager

Mobile:+86-13424379660

Email:[email protected]

Add: No. 8 Qiaolin Road, Lingxiang Industrial Park, Qiaotou Town, Dongguan City, Guangdong Province, China.

judy

judy